Cookies help us to use and improve our website. By using this site, you agree to the use of cookies. More information: privacy policy

Connecting systems for timber frame construction

The RICON® S – System holds up to 230 kN and can be used for joints from timber to timber, steel, and concrete. The connectors can be installed fully concealed or visible with only 35mm (1 1/2″) of travel required to engage. The RICON® Connecting System is a unique connector for main and secondary beam joints and can be installed on beams with a width as little as 50mm. The GIGANT Connecting System was the first connector to be installed with screws in a perpendicular direction in the end grain and revolutionized the timber industry.

KNAPP® connecting systems provide a very high degree of prefabrication, is compliant with the (ETA) European certification, and has the CE-marking. Regular external inspection guarantees maximum security for contractors, architects, manufacturers, engineers and owners. All KNAPP® connectors can simply be snapped in place. The fasteners are recessed and not visible when assembled. In most cases, disassembly is also possible. KNAPP® connectors not only guarantee to meet the highest standards in the manufacturing and assembling process but also makes the structure esthetically pleasing.

Are you from the Americas? Follow the link to view our connectors for Timber Frame and Mass Timber Construction on our US website!

With over 30 years of experience inventing connecting solutions for woodworkers, KNAPP® is proud to say, „we supply the world“. While our main headquarters is located in Austria, KNAPP® has been supplying connectors to the United States and Canada for over 20 years. As the demand for invisible connecting solutions grew, we replied by establishing our U.S. branch in 2017 to better serve the needs of our fellow woodworkers. If you live within North, South, or Central America, please visit KNAPPconnectors.com or email info@KNAPPconnectors.com to be connected with the right representative.

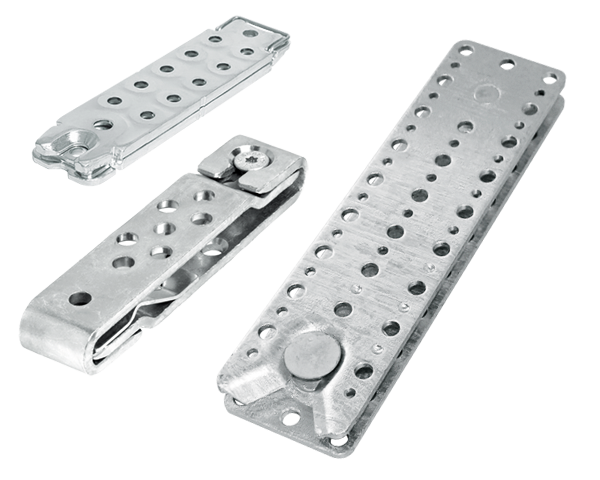

RICON® | The connector for main and secondary beam joints up to 23,4 kN

The main and secondary beam joint connector RICON® consists of two identical connector plates made of steel. An optional lock can be installed to latch the connector. The RICON® is recessed and non-visible, and can be used with timber widths as little as 50 mm. RICON® is available in a single connector set and double connector set for cross joints in six sizes 60, 80, 100, 120, 140 and 160/40.

NEW and improved:

- Better grip on the timber by means of a star-shaped embossing on the backside of the connector plate.

- Mounting also on intermediate layers up to 26 mm (i.e. OSB).

- Special coating for increased corrosion resistance for indoor swimming pools, riding halls, stables and farm buildings (tested).

- Approval for off-centered glass loads up to 860 kg given by an additional reinforcing plate.

- ETA extension for Hardwood (i.e. oak, larch, beech)

- Concealed – connectors are recessed and non-visible.

- Disassembly and reassembly possible if needed.

- High degree of prefabrication – fast and exact assembly on-site.

- Universal – connectors can fasten timber to timber, to steel and to concrete components.

- Unique – can also be used for polygon façades.

- Slim timber dimension – can be mounted on timber with thickness as little as 50mm and up to 450mm.

- Labor efficient – no additional screwing or nailing needed when assembled on site.

- Adjustable – can be adjusted according to joints intervals and construction tolerances.

- Versatile – can be used for single joint and double joint applications.

- Flexible – direction of assembly can even be from the outside towards the inside and from down upwards.

- Safety – fire resistance according to (DIN 4102-2) by 4-sided concealed mounting (R30 ≥ 20 mm, R60 ≥ 40 mm).

- Neutral – can be used in combination with different exterior profile systems such as RP, Schüco, MBJ, Gutmann, RAICO, Stabalux, … etc.

Renovation of the church “Chapelle de la Pureté” (Chapel of purity) with RICON® and RICON® S connectors

Project: Chapelle de la Pureté (Chapel of purity) (F)

Knapp-Connector: RICON®, RICON® S

Architect: Jacques de Welle and Emmanuel de Foresta, Spiridon Kakavas and Antonios lionis (project manager)

Coordination/finances: Association Restauration et Conservation de la Chapelle Bédarride fondation du Patrimoine, Aix-en-Provence

Planning: Cédric Roth-Meyer, www.intuitionbois.com

Builder representation: Elisabeth Hériard-Dubreuill

Builder: Metropole orthodoxe grecque, Paris

Execution: Cédric Roth-Meyer, Bastien Milhau, frédéric tourneux, Matthias Pfister

Press article: Holzbau-Magazin 2012

Brochure: Referenzprojekt Kirchensanierung

“Wal” in Friedrichskoog (D) – wooden frame construction with RICON® system

Project: Indoor playground „Wal“ (Whale) in Friedrichskoog (D), www.wal-friedrichskoog.de

Knapp-Connector: RICON® und GIGANT

Architect: rimpf Architektur, www.rimpf.de

Timber Company: Gebr. Schütt KG GmbH & Co., www.schuett-holzbau.de

Press article: Sonderdruck mikado 1/2009

Brochure:: Referenzprojekt Indoorspielpark Wal

Frankfurt Book Fair Pavilion (D) - Timber self-supporting structure with DUO 35 ml and RICON®

Project: Frankfurt Book Fair Pavilion

Connector: DUO 35mL, RICON®

Architect: schneider+schumacher Planungsgesellschaft, www.schneider-schumacher.de

Planning: Bollinger + Grohmann International GmbH, www.bollinger-grohmann.com

Structural engineering: IPB Planungen AG

Carpenter: Holzbau Amann GmbH, www.holzbau-amann.de

Client: Frankfurter Buchmesse GmbH

Year of construction: 2018, installed in about 7 days

Construction: Timber structure of laminated veneer lumber with a translucent membrane and framework with concealed connecting systems

Address: AGORA book fair in Frankfurt am Main

Enclosed space: 480m², 6.5m in height

Details: 300 seating capacity, total standing 400 people

Press article (German): https://www.detail.de/blog-artikel/parametrische-poesie-frankfurt-pavilion-von-schneider-schumacher-33089/

A to-go library

A pavilion at the Frankfurt Book Fair with 400 people standing capacity stands for a temporary library. The horizontal boards between the ribs give rigidity to the structure and serve at the same time as bookshelves. The pavilion consists of three shell-shaped timber frames that are superimposed and covered with a membrane made of recycled plastic (PVC). The lateral bracing members are connected to the rib panels with the connectors RICON® and DUO 35 enabling both easy assembly and disassembly.

„Both connectors can be assembled several times and are still strong even after the tenth assembly,“ says Hendrik Pfeffinger, project manager at Holzbau Amann.

Renovation of a wooden balcony - Villa Möwe in Heiligendamm with RICON® stainless steel

Knapp-Connector: RICON® stainless steel

Planning:

Timber construction: Zimmerei & Dachbau Sascha Jenß, www.holzbau-jenss.de

Builder: Private Residenzen Heiligendamm, www.private-residenzen.de

Method of construction: Swiss chalet style

Newly built wooden balcony with RICON® stainless steel

Knapp-Connector: RICON® stainless steel

Planning: Architekturbüro Büschel + Partner GbR

Timber construction: Frank Matthies – Die Zimmerei, www.fm-diezimmerei.de

Contractor: Dipl.-Ing. G. Ahnert, Ingenieurbüro für Bautechnik, www.ahnert-ingenieure.de

Builder: Wohnungsgenossenschaft Raschelberg e. G., www.wg-raschelbergeg.de

Method of construction: 2-storey wooden balcony

Address: Niederhäslicher Straße 5, 01705 Freital

Height/Length/Width: 5,56m / 2,87m / 1,68m (without railing)

Goethe Tower in Frankfurt (D) – Round pillars with RICON® stainless steel

Project: Goethe Tower – Tallest public wooden construction in Germany

Connector: RICON 60/30 EA stainless steel and Ricon 80/30 EA stainless steel

Architect / Structural engineering: Wirth-Haker, Marie- Curie-Str. 1 79100 Freiburg, www.ing-wh.de

Carpenter: Holzbau Amann GmbH, www.holzbau-amann.de

Client: Town Council, Frankfurt am Main – Department of parks, Adam-Riese-Str. 25 60327, Frankfurt am Main

Construction period: October 2019 – July 2020

Design: Spanish chestnut circular pillar

Location: Frankfurt city forest – Sachsenhausen

Details:

- Height: 43.3 metre

- Area: 18m²

- Reconstruction costs: about 2.4 million euros

- 120 cubic meters (about 72 tonnes) of glued laminated timber of sweet chestnut (48 circular columns, struts, beams)

- 30 cubic meters (about 24 tonnes) of oak (steps, platform, railing)

- 35 tons of steel (stair stringers, connectors)

Steps:

- 12th October 2017: Destroyed in a fire due to arson

- October / November 2017: Online survey, 78% of respondents want a true-to-the-original reconstruction.

- April 2018: Commissioning of the Wirth-Haker engineering office with the project and structural planning

- August 2019: Commissioning of the company Holzbau Amann GmbH with the timber construction work, building permit was issued.

- October 2019: Starting groundwork

- November 2019: Project-related type approval for glued laminated timber made of sweet chestnut is granted

- December 2019: Order of glued laminated timber

- from April 2020: Prefabrication / timber framing

- July 2020: Wood construction assembly

Wikipedia: https://en.wikipedia.org/wiki/Goethe_Tower

The characteristic values can be found in our interactive load bearing excel table. Further services are a design tool and KNAPP DC-Engineering design software from Dietrich’s. The design for all requirements can be found in our planner service:

GIGANT | The connector for main and secondary beam up to 39 kN

The Gigant connecting system consists of two identical connector brackets made of steel. The brackets are recesseed and screwed on to the timber components. The timbers are joined as the brackets hook into each other in a dove tail-like manner. The Gigant is used in timber structures, such as canopys, pergulas, sunrooms, timber homes and even ingeneered timber structures. The Gigant connectors is non-visible, self-tightening and adjustable, with no aditional screwing or nailing reqired to assemble the timber structure on site. An optional lock can be installed to latch the connector against the slide-in direction. The Gigant is availabe in three sizes, 120/40, 150/40 and 180/40.

NEW and improved:

- ETA extension for Hardwood (i.e. oak, larch, beech)

- Available in hot-dip galvanizing for higher corrosion resistance.

- Concealed – connectors are recessed and non-visible.

- Highly loadable – in all directions.

- Short hooking way – only 50mm.

- Self-tightening – due to dove tail-like mechanism.

- Optional locking clip – latches the fastener against slide-in direction (e.g. wind suction forces).

- Disassembly and reassembly possible if needed.

- Fire resistance according to (DIN 4102-2) by 4-sided concealed mounting (R30 ≥ 20 mm, R60 ≥ 40 mm).

“Wal” in Friedrichskoog (D) – wooden frame construction with RICON® system

Project: Indoor playground „Wal“ (Whale) in Friedrichskoog (D), www.wal-friedrichskoog.de

Knapp-Connector: RICON® und GIGANT

Architect: rimpf Architektur, www.rimpf.de

Timber Company: Gebr. Schütt KG GmbH & Co., www.schuett-holzbau.de

Press article: Sonderdruck mikado 1/2009

Brochure:: Referenzprojekt Indoorspielpark Wal

The characteristic values can be found in our interactive load bearing excel table. Further services are a design tool and KNAPP DC-Engineering design software from Dietrich’s. The design for all requirements can be found in our planner service:

RICON® S | The connector for main and secondary beam up to 230 kN

The heavy load main and secondary beam connector RICON® S consists of two identical connector plates, made of galvanized steel. The plates are screwed onto the timber, steel, and/or concrete components. The components are joined as the plates hook into each other in a dovetail-like manner. The RICON® S is used in residential and commercial timber construction, as well as engineered timber structures. You can meet the needed load capacity by using the appropriate amount of RICON® S CS screws.

RICON® S is available in five sizes with six different collar bolt variants to meet all connection requirements for wood, steel, and concrete:

VS = welded collar bolt, for highest load capacities

EK = adjustable screw collar bolt, for tolerance adjustment

GK = spring-loaded collar bolt for special assembly requirements

VK = screwed collar bolt, for moderate charge capacities

S80 adjustable with insert screw = for tolerance compensation up to 5mm

Charact. load carrying capacity F2,Rk in insertion direction applies only to the use of original KNAPP® CS-screws according to ETA-10/0189 (25/08/2022).

NEW and improved:

- Approvals ETA, UKTA, ICC-ES.

- Disassembly and reassembly possible if needed.

- A high degree of prefabrication – fast and exact assembly on-site.

- Universal – connectors can fasten timber to timber, to steel, and to concrete.

- Concealed – connectors are recessed and non-visible.

- Simple – self-taping screws without pre-drilling.

- Easy – assembly made easy due to the V-shaped bracket and only 3.5 cm hook way.

- Adjustable collar bolt – can be adjusted according to joints intervals and even up to 5mm in timber length tolerances.

- Optional locking clip – latches the fastener against slide-in direction (e.g. wind suction forces).

- Fire resistance according to (DIN 4102-2) by 4-sided concealed mounting (R30 ≥ 20 mm, R60 ≥ 40 mm).

Connection options for wood, wood-based materials, steel, concrete

Download Project Reference Community house (DE) Hünstetten-Oberlibbach (PDF)

Mastercard VIP Lounge in Kitzbühel (A) – Wooden facade with KNAPP® connectors

Project: Mastercard VIP Lounge Hahnenkamm Streif Kitzbühel finish area slope

Connector: MEGANT®, RICON® S, RICON® and WALCO® V

Architect / Planning: Ing. Lukas Moser, Kuchler Blockhaus (P. Lienbacher Holzbauwerk GmbH, www.kuchler-blockhaus.com)

Structural engineering: Torsten Langejürgen, dimensioning Knapp GmbH

Carpenter: Kuchler Blockhaus Lienbacher Holzbauwerk GmbH, www.kuchler-blockhaus.com

Client: WWP Weirather-Wenzel & Partner GmbH ,www.wwp-group.com/de

Building Type: Cross laminated timber with insulation and wooden facade

Construction time: Start of 2019

Address: Kitzbühel AT

Gross building volume/m²: 240m²

Press articles:

HUF Haus - WALCO® V

Project: HUF Haus ART 3

Knapp-Connector: RICON® S and WALCO® V

Architect: Josef Günster

Planning: HUF HAUS

Timber construction: HUF HAUS

Builder: Private client

Year of construction: 2020

Duration of construction: About 2 weeks for construction of the building

Method of construction: Modern half-timbered architecture with glued timber framework construction

Gross building volume: 219 m²

Red Bull Energy Station Formula 1

Project: Red Bull Energy Station Formula 1 (Event building)

Timber construction: Complete Timber construction with an alpine style

Knapp-Connector: RICON® S for Tragkonstruktion, WALCO® V for the facade

Design & Planning: Claudio Hatz, Salzburg, www.claudio-hatz.at

Static: KPZT Kurt Pock, Klagenfurt, www.kurtpock.at

Steel Construction: Leuprecht, Höfen and Asen, Seekirchen

Facade: Walch & Partner, Reutte, www.walch.co.at

Wood Construction: Holzbau Saurer GmbH & Go KG, Höfen/Tirol, www.holzbau-saurer.com

Builder: Red Bull GmbH, Fuschl, www.redbull.com/at-de

Year of construction: will be assembled up and dismantled up to 200 times in 2019

Gross building volume/m2: 1221 m2, column girder system which is 32 m long, 14 m wide and 11 m high.

Address: Worldwide for Formula 1 teams -Aston Martin Red Bull Racing and Scuderia Toro Rosso- with a planned utilization of 10 years.

Picture Source: Andreas AUFSCHNAITER / Red Bull content pool.

Timber construction engineering – Indoor swimming pool at Ried im Innkreis (AT)

Project: Indoor swimming pool at Ried im Innkreis (AT)

Knapp-Connector: RICON® S

Architect: Gärtner + Neururer ZT GmbH, Stadtplatz 14, A-4840 Vöcklabruck, www.gaertner-neururer.at

Planning: ISG Innviertler Gemeinnützige Wohnungs- und Siedlungsgenossenschaft reg. Gen.m.b.H., Riedauer Straße 28, A-4910 Ried im Innkreis, www.isg-wohnen.at

Structural engineering: DI Weilhartner ZT GmbH Ing. Konsulenten für Bauingenieurwesen, A-4910 Ried im Innkreis, www.stahlbetonbau.at, www.ztw.at

Timber construction: Structurlam, Penticton, BC (CAN), www.structurlam.com

Builder: Stadtgemeinde Ried, Hauptplatz 12, A-4910 Ried im Innkreis www.ried.at

Year of construction: 2016

Method of construction: Solid wood glue construction

Address: Volksfeststraße 14, A-4910 Ried im Innkreis, www.freizeitbad-ried.at

Gross building volume: 27.000 m²

Renovation of the church “Chapelle de la Pureté” (Chapel of purity) with RICON® and RICON® S connectors

Project: Chapelle de la Pureté (Chapel of purity) (F)

Knapp-Connector: RICON®, RICON® S

Architect: Jacques de Welle and Emmanuel de Foresta, Spiridon Kakavas and Antonios lionis (project manager)

Coordination/finances: Association Restauration et Conservation de la Chapelle Bédarride fondation du Patrimoine, Aix-en-Provence

Planning: Cédric Roth-Meyer, www.intuitionbois.com

Builder representation: Elisabeth Hériard-Dubreuill

Builder: Metropole orthodoxe grecque, Paris

Execution: Cédric Roth-Meyer, Bastien Milhau, frédéric tourneux, Matthias Pfister

Press article: Holzbau-Magazin 2012

Brochure: Referenzprojekt Kirchensanierung

The characteristic values can be found in our interactive load bearing excel table. Further services are a design tool and KNAPP DC-Engineering design software from Dietrich’s. The design for all requirements can be found in our planner service:

T-JOINT | Screw connector made of cast iron or stainless steel for angular screwed joints up to 15 kN

T-joint connectors for flush 30º and 45º angular screwed joints for timber construction.

The T-Joint has no protruding connector parts, because it is screwed flush. The high-quality steel cylinder connector part can be readjusted at any time and joint-sealed without visible joints. The T-Joint is universal and is used for steel and wood tensile joint in straight and angled wall connections. The elements can be demounted easily.

- Flush – no protruding connector parts

- Tightening – no gaps, can be adjusted at any time

- Demountable – disassemble and re-assemble multiple times

- Fast – high degree of pre-manufacturing

- Universal – suitable for wood and steel joints

- Versatile – for flush and corner wall joints

- Simple – easy positioning in the borehole

Pavilion in the yak enclosure of the zoo Tierpark Hellabrunn (D) – Timber frame construction with T-JOINT

Project: Pavilion in the yak enclosure of the zoo Tierpark Hellabrunn

Connector: T-JOINT D20

Planning: Radim Rozehnal, deputy director of the planning division of the zoo Tierpark Hellabrunn

Carpenter: Greinwald GmbH, D-82435 Bad Bayersoien, www.zimmerei-greinwald.de

Client: Tierpark Hellabrunn, www.hellabrunn.de

Year of construction: 2020

Construction: Timber-Frame Construction

Address: Tierpark Hellabrunn, Tierparkstrasse 30, D-81543 Munich

Details: Seven larch columns connected to HEB180 beams are anchored into sleeve foundation. The roof is made of two larch cross laminated timber rings and 32 poles made of 57/95 mm laminated veneer lumber. The whole wooden structure has been prefabricated in the factory and mounted on the building site in one day.

Project reference: "Domi-Mone Single Family Home"

Project: Construction of a home „Domi-Mone“

Connector: T-JOINT, MATEO stepped dowel nail in beech

Timber constructor: Lengauer GmbH, www.lengauer-holz.at

Year of construction: 2019

Type of construction: KLH glulam, visible area sanded, miter corners.

The result: „We are happy,“ says Lengauer, „especially with the finish. All went well. There were no unforeseen incidents, no forgotten screw heads damaging the tool during milling, no protruding metal parts, and no inaccurate positioning. It saved us a lot of time, work, and money“.

Report about T-JOINT in HOLZKURIER 05.2020

Report about MATEO in holzmagazin 02.2020

Report about MATEO in Tischler Journal 04.2020

Report about the construction project BSP Special 2019

Image source: Lengauer GmbH in Neumarkt (A) für Montagefotos

Image source: Knapp GmbH (A) für Projektfotos

MATEO timber peg | Wooden connector for traditional timber construction with a couple of hammer blows

- Wood-wood connection – ecological and proven

- Simple processing

- Pre-drilling in the factory or on the construction site

- Self-tightening

- Traditional design

- Metal-free connection

- Predictable fire resistance

- Self centering – easy to insert due to stepped design

Project reference: "Domi-Mone Single Family Home"

Project: Construction of a home „Domi-Mone“

Connector: T-JOINT, MATEO stepped dowel nail in beech

Timber constructor: Lengauer GmbH, www.lengauer-holz.at

Year of construction: 2019

Type of construction: KLH glulam, visible area sanded, miter corners.

The result: „We are happy,“ says Lengauer, „especially with the finish. All went well. There were no unforeseen incidents, no forgotten screw heads damaging the tool during milling, no protruding metal parts, and no inaccurate positioning. It saved us a lot of time, work, and money“.

Report about T-JOINT in HOLZKURIER 05.2020

Report about MATEO in holzmagazin 02.2020

Report about MATEO in Tischler Journal 04.2020

Report about the construction project BSP Special 2019

Image source: Lengauer GmbH in Neumarkt (A) für Montagefotos

Image source: Knapp GmbH (A) für Projektfotos