Cookies help us to use and improve our website. By using this site, you agree to the use of cookies. More information: privacy policy

Connecting systems for advanced residential buildings

On the following pages you will find our connecting systems for advanced residential building.

The WALCO® V wall connecting system allows fast and precise assembly through a simple „dove tail“ mechanism. Even advanced, fully pre-manufactured walls (including windows and doors) can simply be snapped together on site without any screwing or nailing. This applies to all advanced multi level closed wall prefab and modular structures, timber frame structures, as well as fastening systems for facades.

KNAPP® connecting systems provides a very high degree of prefabrication, is compliant to the (ETA) European certification and has the CE-marking. Regular external inspection guarantees maximum security for contractors, architects, manufacturers, engineers and owners. All KNAPP® connectors can simply be snapped in place. The fasteners are recessed and not visible when assembled. In most cases, disassembly is possible.

KNAPP® connectors not only guarantee to meet the highest standards in the manufacturing and assembling process, but also are esthetically pleasing.

Are you from the Americas? Follow the link to view our connectors for Modular and Prefab Walls on our US website!

With over 30 years of experience inventing connecting solutions for woodworkers, KNAPP® is proud to say, „we supply the world“. While our main headquarters is located in Austria, KNAPP® has been supplying connectors to the United States and Canada for over 20 years. As the demand for invisible connecting solutions grew, we replied by establishing our U.S. branch in 2017 to better serve the needs of our fellow woodworkers. If you live within North, South, or Central America, please visit KNAPPconnectors.com or email info@KNAPPconnectors.com to be connected with the right representative.

WALCO® V | The connector for prefab-walls up to 16 kN

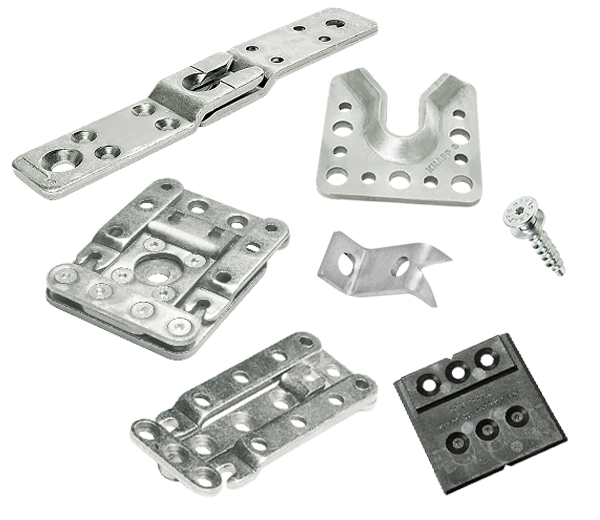

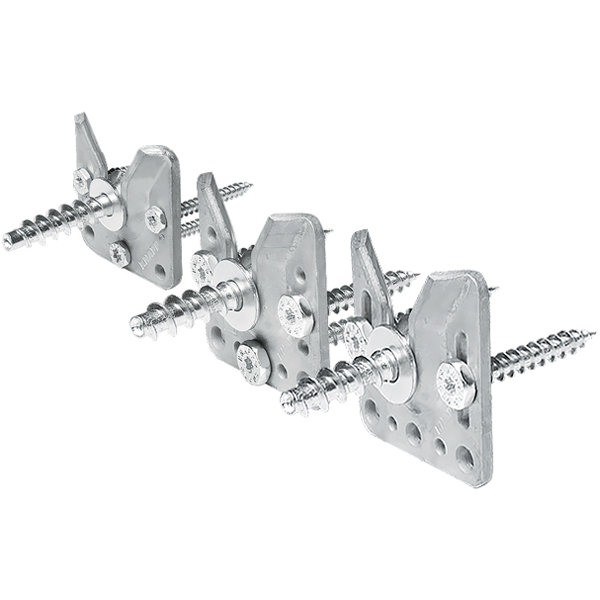

The WALCO® V wall connector set consists of a “dove tail” shaped hot-dip galvanized bracket and a specially shaped counterpart screw. An optional lock can be installed to latch the connection against the slide-in direction. Prefabricated walls can be connected to each other within just one minute. Assembly is made simple through the spacious V-shaped bracket and only needs a 35 mm (1 ½ inch) distance to engage the screw with the bracket. WALCO®V is available in two sizes (60 and 80), and each size in four different kinds (KS, VK, EH, GH*).

- Universal – connections can be made from timber to timber, to steel and to concrete.

- For timber widths from 80 mm upwards

- Easy – no recess of bracket needed if the hight of the planking is 13/15 mm (the counter part screw can be recessed on the other side).

- Effective – fast and accurate assembly on site – fully prefabricated walls are assembled without any screwing or nailing.

- Stable from the first wall corner on

- Saves labor – quick and easy assembly through spacious V-shaped bracket.

- Unique – screws are screwed directly in the component with or without interlayer

- Flexible – assembly to the last wall and even interior walls.

- Adjustable and esthetically pleasing – connectors are recessed and therfore not visible when assembled. Screws can be readjusted in perpendicular direction to compensate building tolerances e.g. for seals and gaskets.

- ETA certified (even for hardwood).

*KS = Hex-head screw, VK= collar bolt holding screw, EH=Adjustable retaining screw, GH=Retaining spring holding screw

Research and Workshop Building in Diemerstein

Knapp-Connector: WALCO® V60 / RICON® 100×40 EA / DA

Architect:

Design, Univ.-Prof. Stephan Birk (since April 2021 TU Munich), Marcel Balsen, Nik Beiler

Structural planning: planning and materials, Univ.-Prof. Dr.-Ing. Jürgen Graf, Reiner Klopfer, Viktor Poteschkin, Yannick Braun, Oliver Betha

Manufacturing three-hinge frames and cone adapters Schmeing GmbH & Co. KG, 57399 Kirchhundem, www.dehonit.de

Structural planning:

t-lab wood architecture and wood materials, fatuk, Rhineland-Palatinate Technical University Kaiserslautern-Landau (RPTU), 67663 Kaiserslautern, www.tlab.architektur.rptu.de

Builder:

Production of timber frame : Wilch Holzhaus GmbH

Manufacture of three-hinged frames: Schmeing GmbH & Co. KG

Machining wood: Cltech GmbH & Co. KG

Contractor:

Foundation TU Kaiserslautern, Administration Dr. agr. Annette Mechel, 67663 Kaiserslautern, www.rptu.de

t-lab wood architecture and wood materials, fatuk, Rhineland-Palatinate Technical University Kaiserslautern-Landau (RPTU), 67663 Kaiserslautern, www.tlab.architektur.rptu.de

Engineering:

Drees & Sommer Advanced Building Tech. Stuttgart

Ralf Buchholz

Fire protection consulting:

IBC Engineering-Consult GmbH Mainz

Martin Hermes

Geotechnical report:

Jörg Huber Engineering Office

Dipl.-Ing. J. Huber

Year of construction: 2022

Construction method:

Construction (e.g., glulam wall and roof)

Structural System: Three-hinged frames made of BauBuche (bars) and synthetic resin-bonded wood (nodes)

Wooden frame and Insulation layer

Address: Diemerstein 6, 67468 Frankenstein, Germany

Building space: approx. 360 m²

Image sources: t-lab/Technische Universität Kaiserslautern, Andreas Labes

HUF Haus - WALCO® V

Project: HUF Haus ART 3

Knapp-Connector: RICON® S and WALCO® V

Architect: Josef Günster

Planning: HUF HAUS

Timber construction: HUF HAUS

Builder: Private client

Year of construction: 2020

Duration of construction: About 2 weeks for construction of the building

Method of construction: Modern half-timbered architecture with glued timber framework construction

Gross building volume: 219 m²

Housebuilding – Riedpark in Lauchringen (D)

Project: Residential and commercial real estate in Riedpark / Lauchringen (D)

Knapp-Connector: WALCO® V and RICON® S

Architect: Jörg Kaiser Architekturbüro, Hauptstr. 47, 79787 Lauchringen, www.architektkaiser.de

Structural engineering: Lignotrend Produktions GmbH, Landstr. 25, 79809 Weilheim-Bannholz, www.lignotrend.de

Timber construction: Holzbau-Amann GmbH, Albtalstr. 1, 79809 Weilheim-Bannholz, www.holzbau-amann.de

Jonathan Loderbauer, Kapellenstr. 3, 79737 Herrischried, www.die-holzerei.de

Holzbau & Zimmerei Maise, Stiegstr. 27, 79774 Albbruck-Unteralpfen, www.holzbau-maise.de

Year of construction: 2017

Address: 79787 Lauchringen (BW)

Press release: Südkurier vom 16.02.2017

Stalls with WALCO®

Project: Demountable stalls for the District Museum Association Schloss Landeck (AT)

Method of construction: Timber frame construction

Knapp-Connector: WALCO® V

Timber construction: Students of the HTL Imst with Ing. Dipl.-Päd. Gerhard Peer HTL Imst / Building Technology Department, www.htl-imst.at

Architect: HTL Imst / Building Technology Department

Housebuilding – Single-family houses and urban villas (AT)

Project: Prefabricated houses (AT)

Method of construction: Frame construction

Knapp-Connector: WALCO® V

Timber construction: Genböck Haus Genböck & Möseneder GmbH, www.genboeck.at

Architect: Genböck Haus Genböck & Möseneder GmbH

Energy usage: For example passive houses, energy-plus-houses

Housebuilding – Addition of storeys to a multi-family house (DE)

Project: Addition of storeys to a multi-family house (DE)

Knapp-Connector: WALCO® V

Builder: Braintec GmbH, 83132 Pittenhart, www.brain-tec.net

Architect: ARCHITEKTURBÜRO ANSELM KANNO, www.architekt-kanno.de

Timber constructor: Zimmerei Holzbau – Schröder, www.holzbau-schroeder.com

Structural engineering: Andreas Reinicke, 21354 Bleckede

Method of construction: Timber frame construction

Construction time: 8 months

Press article: mikado 5/2014

Housebuilding – House^3 (US-MN)

Project: Prefabricated house – House^3 (US-MN)

Knapp-Connector: WALCO® V

Builder / Project developer / Architect: University of Minnesota Duluth, www.d.umn.edu

Details: The most unique characteristic of House³ is its ability to be transported, assembled, disassembled, and redeployed. House³ uses proprietary wall connectors to ensure that prefabricated wood framewalls can be slid into place directly on site with minimal effort. Most importantly, the connectors allow for a clean disassembly and repacking of the module for relocation.

Brochure: Containerhäuser USA

Housebuilding – New constructed housing complex in Sistrans (AT)

Project: Prefabricated house – Housing complex in Sistrans (AT)

Knapp-Connector: WALCO® V

Architect: Teamk2 (Architects), www.teamk2.com

Timber construction: Schafferer Holzbau, www.schafferer.at

Press article: mikado 3/2011

Housebuilding - Wasserferienwelt „Im Jaich“ / Rügen (DE)

Project: Prefabricated houses – Wasserferienwelt „Im Jaich“ / Rügen (DE), www.im-jaich.de

Knapp-Connector: WALCO® V

Architect: Drebing Ehmke Architekten, www.drebingehmke.de

Timber construction: HOKO Fertighaus GmbH, www.hoko-haus.de

Structural engineering: IBAST Ingenieurbüro für Baustatik, www.ibast.de

Construction time: June 2009 to October 2010

Method of construction: Wooden frame construction

Press article: mikado 1-2/2011

Brochure: Referenzprojekt Bootshäuser Rügen

Housebuilding – Wooden four-storey building in Bad Aibling (DE)

Project: Prefabricated four-storey building in Bad Aibling (DE)

Knapp-Connector: WALCO® V

Builder: B&O-Gruppe Bad Aibling, www.bo-wonungswirtschaft.de

Planning: SCHANKULA Architekten/Diplomingenieure, www.schankula.com

Timber construction: Huber & Sohn GmbH & Co. KG, www.huber-sohn.de

Press article: mikado 10/2010

Housebuilding – Single-family house / Rigi (CH)

Project: Prefabricated single-family house / Rigi (CH)

Method of construction: Wooden post-and-plank construction

Knapp-Connector: WALCO® V

Timber construction: Die Holzwerkstatt Matthias Ebi, Nöggenschwiel, www.ebi-holzwerkstatt.de

Architect + Planning: Schweizer Naturhaus CH-Koblenz, www.natur-haus.ch

Structural engineering: Ingenieurbüro Rotkamm Albbruck, www.rotkamm.de

Energy usage: Low energy according to Swiss Standard

Construction time: 5 months

Press article: mikado 10/2011

Brochure: Referenzprojekt Holzfertigteilhaus mit Helikoptermontage Rigi

“Mc Cube” – Modular house to put together

Project: Modular house to put together / Winklarn (AT)

Knapp-Connector: WALCO® V

Builder: Martina Kies

Architect: Mc Cube Homes GesmbH iG, www.mccube.at

Timber constructor: Fahrenberger GmbH, www.zimmerei-f.at

Finalized: Autumn 2014

Press article: momag 326 | November 2014

Housebuilding – international competition “Solar Decathlon Europe 2010”

Project: Prefabricated houses for the Solar Decathlon Europe 2010 – 2nd place in the overall ranking (ESP)

Knapp-Connector: WALCO® V, RICON®, QUATRO 65

Builder/Project developer/Architect: TEAM IKAROS BAVARIA | FH Rosenheim, www.solar-decathlon.fh-rosenheim.de

Details: It remained exciting until the end: on the evening of the last competition day of the first international university competition „Solar Decathlon Europe 2010“ on European soil, the 17 participant teams came together for the award ceremony. Richard King, the inventor of the „Solar Decathlon“ in the US, welcomed the Decathletes. Then the winners were determined: Rosenheim took the second place – for the outstanding performance of the student „Team IKAROS Bavaria“ of the University of Applied Sciences – University of Applied Sciences Rosenheim.

Brochure: Solar Decathlon Europe 2010

Housebuilding – Nine housing units in a backyard (GBR)

Project: Prefabricated houses – Nine housing units in a backyard, London-Harlesden (GBR)

Knapp-Connector: WALCO® V, WALCO® 40

Builder / Project developer / Architect: SUSD Ltd., www.susd.co.uk

Structural engineering: Dr. Dubslaff & Rosenkranz D-59939 Olsberg, www.rdr-energie.de

Timber construction: Holzbau Becker & Sohn GmbH, Kolpingstraße 4, 59964 Medebach, www.becker360.de/referenzen/wohnhaeuser

Construction time: December 2008 – December 2010

Method of construction: Wooden frame and plank pile design

Gross building volume: 2342 m³ / 897 m²

Press article: mikado 12/2010

Brochure: Referenzprojekt Urbaner Holzbau London

WALCO® Z | The wall connector for timber frame constructions up to 11 kN

The WALCO® Z set consists of two identical brackets made out of blue-galvanized steel. Commonly used gaskets can be installed on the prefabricated wall panels. When sliding the wall panels together, the brackets hook into each other in a dovetail-like manner and tighten up the connection. This allows the wall panels to be pre-manufactured to a large degree in a superior and advanced quality and then connected on site with no screwing or nailing needed.

- Efficient wall connectors for timber frame and wood panel construction.F

- For timber widths from 60 mm and upwards.

- Large degree of prefabrication – no screwing or nailing on-site.

- Simple and easy – the wall panels are snapped together.

- Stable from the first wall corner on

- For timber structures according to DIN 1052 and Eurocode 5 (EN 1995-1-1).

- ETA certified (even for hardwood).

Alpegg Chalets in Waidring (A) – Wooden stand and frame construction with WALCO® Z40

Project: Alpegg Chalets in Waidring (A)

Connector: WALCO® Z40

Architect / Structural engineering: Architektengruppe P3, A-6380 St. Johann in Tirol, Neubauweg 13, www.architektengruppe-p3.at

Carpenter: Holzbau Foidl, A-6391 Fieberbrunn, Rosenegg 36, www.holzbau-foidl.at

Client: Cornelia and Roland Defrancesco

Year of construction: 2016

Method of construction: Wooden stand and frame construction with planking

Address: Alpegg 13, A-6384 Waidring, Austria

Details: Three chalets with adjoining house

Link: www.alpegg.com

To connect very fast: Alpegg Chalets

Hotel construction is a very demanding sector, and it is a must to work quickly, precisely, and preferably with invisible systems. It is important that guests feel comfortable. Therefore, Foidl Carpentry relied on prefabricated wall elements for constructing the three „Alpegg Chalets“ and a home in Waidring, Austria.

With the KNAPP WALCO® Z40 connector, the frame walls were connected quickly, securely, and invisibly, so the assembly of the building shell took only a few days. „We use the WALCO® Z40 connector for all our timber frame constructions“, says Hannes Rettenwander, project manager at Foidl. “This connector allows quick and easy assembly and adjustment of the wall elements in all directions, both vertically and horizontally. It brings, as such, a great advantage to timber construction: quick assembly and time savings.”

The hotel owners, Cornelia, and Roland Defrancesco had time to do up a lovely interior design.

A success: the Alpegg won the prestigious World Ski Awards

Housebuilding – Nine housing units in a backyard (GBR)

Project: Prefabricated houses – Nine housing units in a backyard, London-Harlesden (GBR)

Knapp-Connector: WALCO® V, WALCO® 40

Builder / Project developer / Architect: SUSD Ltd., www.susd.co.uk

Structural engineering: Dr. Dubslaff & Rosenkranz D-59939 Olsberg, www.rdr-energie.de

Timber construction: Holzbau Becker & Sohn GmbH, Kolpingstraße 4, 59964 Medebach, www.becker360.de/referenzen/wohnhaeuser

Construction time: December 2008 – December 2010

Method of construction: Wooden frame and plank pile design

Gross building volume: 2342 m³ / 897 m²

Press article: mikado 12/2010

Brochure: Referenzprojekt Urbaner Holzbau London

WALCO® | Connectors for facades, walls and modular structures up to 21,3 kN

- Universal connection of facades, wall- and room modules to solid wood, wood-based materials, steel, and concrete as well as brickwork

- Fast and precise assembly and disassembly on site due to its V-shaped system

- High level of prefabrication

- Adjustable to the millimetre

- Outstanding safety and stability

ORF studio for the Nordic World Ski Championships Oberstdorf 2021 - Modular construction with WALCO®

Project: sustainable and mobile ORF studio at the Nordic World Ski Championships Oberstdorf 2021

Connector: WALCO® 80 VK, WALCO® V80

Structural engineering & Assembly: GETEC Eventtechnik GmbH, www.getec-group.com

Timber construction: Noritec GmbH (HASSLACHER Holding GmbH), www.hasslacher.com

Period of construction: one day (with interior)

Method of construction: Modular construction with Hasslacher Cross Laminated Timber

Gross building volume: 50m²

Details (in German):

https://www.holzbauaustria.at/news/2021/03/nachhaltiges-und-mobiles-orf-studio.html

https://www.facebook.com/pg/geteceventtechnik/posts/

https://eventelevator.de/storys/getec-eventtechnik-bei-der-nordischen-ski-wm/

https://www.hasslacher.com/nordische-ski-wm-2021-in-oberstdorf

WALCO® BOLT

- Stable and concealed connection for prefabricated wall elements made of wood and CLT, as well as connections between wood, steel and concrete

- The slotted holes of the WALCO® 80 base plate allow for readjustment when attached with screws

- Positioning tolerance +/- 2 mm for later compensation of variations on the building site

- Loadable with tension as well as perpendicular to the insertion direction

WALCO® PIPE

- Stable and concealed connection for prefa. wall elements made of wood, CLT, or similar materials

- Modular column connector for load bearing connection

- Precise alignment of wall elements in combination with with WALCO® V

- Easy to dismantle and reassemble due to the screwed-in clamping bolts

- Lifting aid for moving the wall elements

Wood Rocks in the Voralberg with WALCO® Pipe

Projects: Heldenstraße in Feldkirch / Vorarlberg and Turteltaubweg in Dornbirn / Vorarlberg, Austria

Connectors: WALCO® Pipe (925 Connectors)

Architect: Schnetzer/Kreuzer, www.schnetzer-kreuzer.at

Design: Start 2020 / WoodRocks Bau GmbH

Structural engineering: merz kley partner GmbH

Timber construction: WoodRocks Bau GmbH

General contractor:

Heldenstraße: Wohnbauselbsthilfe Vorarlberger gemeinnützige GmbH

Turteltaubweg: Schoren Apartments KG

Construction Time:

08/2021 – 01/2022 Heldenstraße (Feldkirchen)

02/2022 – 07/2022 Turteltaubweg (Dornbirn)

Construction: Lean Construction

Address:

Feldkirch/Vorarlberg, Heldenstraße

Dornbirn/Vorarlberg, Turteltaubweg

Details:

Feldkirch/Vorarlberg Heldenstraße: Three-storey building ,13 flats with two to four rooms

Dornbirn/Vorarlberg Turteltaubweg: Four-storey building, 21micro-apartments

Press article: https://www.holzbauaustria.at/architektur/2022/04/woodrocks-gebaeude-feldkirch-heldenstrasse.html

WALCO® L and T | Wall-floor anchors

- Complete prefabrication of the walls in the factory

- High absorption of tensile and shear forces due to the anchoring in the wall axis

- Tie rods and angle brackets guarantee stable anchoring of the prefabricated walls

- Easy to transport (no protruding parts)

- Short assembly time, time savings of up to 20 minutes per wall

House made using solid wood panels

Knapp-Connector: WALCO L, WALCO V 80 VK

Architect: Fa. Zeh and Engineer’s Office Schwärzler Oberreute

Structural engineering: Engineer’s Office Schwärzler Oberreute

Timber construction: Ulrich Zeh GmbH & Co. KG

Contractor: Riegg/ Krämer Goppertsweiler Halde 16, 88099 Neukirch (DE)

Construction year: 2021

Method of construction: Solid wood construction

Address: Goppertsweiler Halde 16, 88099 Neukirch (DE)

Gross building volume: 152m³ / 227m²

Details: Solid wood houses made of wood dowelled multi-layered walls

T-JOINT | Screw connector made of cast iron or stainless steel for angular screwed joints up to 15 kN

T-joint connectors for flush 30º and 45º angular screwed joints for timber construction.

The T-Joint has no protruding connector parts, because it is screwed flush. The high-quality steel cylinder connector part can be readjusted at any time and joint-sealed without visible joints. The T-Joint is universal and is used for steel and wood tensile joint in straight and angled wall connections. The elements can be demounted easily.

- Flush – no protruding connector parts

- Tightening – no gaps, can be adjusted at any time

- Demountable – disassemble and re-assemble multiple times

- Fast – high degree of pre-manufacturing

- Universal – suitable for wood and steel joints

- Versatile – for flush and corner wall joints

- Simple – easy positioning in the borehole

Pavilion in the yak enclosure of the zoo Tierpark Hellabrunn (D) – Timber frame construction with T-JOINT

Project: Pavilion in the yak enclosure of the zoo Tierpark Hellabrunn

Connector: T-JOINT D20

Planning: Radim Rozehnal, deputy director of the planning division of the zoo Tierpark Hellabrunn

Carpenter: Greinwald GmbH, D-82435 Bad Bayersoien, www.zimmerei-greinwald.de

Client: Tierpark Hellabrunn, www.hellabrunn.de

Year of construction: 2020

Construction: Timber-Frame Construction

Address: Tierpark Hellabrunn, Tierparkstrasse 30, D-81543 Munich

Details: Seven larch columns connected to HEB180 beams are anchored into sleeve foundation. The roof is made of two larch cross laminated timber rings and 32 poles made of 57/95 mm laminated veneer lumber. The whole wooden structure has been prefabricated in the factory and mounted on the building site in one day.

Project reference: "Domi-Mone Single Family Home"

Project: Construction of a home „Domi-Mone“

Connector: T-JOINT, MATEO stepped dowel nail in beech

Timber constructor: Lengauer GmbH, www.lengauer-holz.at

Year of construction: 2019

Type of construction: KLH glulam, visible area sanded, miter corners.

The result: „We are happy,“ says Lengauer, „especially with the finish. All went well. There were no unforeseen incidents, no forgotten screw heads damaging the tool during milling, no protruding metal parts, and no inaccurate positioning. It saved us a lot of time, work, and money“.

Report about T-JOINT in HOLZKURIER 05.2020

Report about MATEO in holzmagazin 02.2020

Report about MATEO in Tischler Journal 04.2020

Report about the construction project BSP Special 2019

Image source: Lengauer GmbH in Neumarkt (A) für Montagefotos

Image source: Knapp GmbH (A) für Projektfotos

ACRO and BASIS-System | Stable timber connector für pillars and posts, column mounting

QUATRO 65 | Hidden deck, panel and board connector incl. 500 CS-screws

The QUATRO 65 is a connector for decking boards and wall panels. It is mounted easily and is non-visible from the first board up to the last. As a result, the connector offers a perfect appearance and high level of security.

QUATRO 65 is easy to handle for professionals, as well as for DIY home improvements. It can be pre-mounted and the boards or panels are quickly fastened on-site using the connector system.

The greatest benefit of this connector is that it allows the natural movement of the wood. Rainwater is diverted, and as a result the durability of the coating and construction is extended.

The QUATRO 65 is fastened on the bottom side of the boards or panels. The elements are then screwed onto the joists. In case of very hard wood, the screw holes should be pre-drilled.

The mounting template enables an even and precise adjustment of the width of the joint. The proper spacing can also be adjusted using the measured grooves.

- Concealed from the first board to the last

- Constructive wood protection against moisture

- Allows expansion and contraction of wood boards

- Optimal rear ventilation through spacing

- Can be used for timber facades and formwork, for which rear ventilation has been implemented

- Easy installation with mounting templates

- UV and weather-resistant fiberglass reinforced plastic.

Tips:

- Even the best connecting system cannot offset poor quality of some timber. Please ensure that the timber is dry; particularly, avoid timber from the core and spiral-grained boards.

- Recommended length of the boards: maximum 3 m (9.8 ft.).

- Recommended for spacing no smaller than 7 mm between the boards and the joists

- You may pre-drill, particularly with hardwoods, such as oak.

- Follow the installation instructions of your timber supplier.

Housebuilding – international competition “Solar Decathlon Europe 2010”

Project: Prefabricated houses for the Solar Decathlon Europe 2010 – 2nd place in the overall ranking (ESP)

Knapp-Connector: WALCO® V, RICON®, QUATRO 65

Builder/Project developer/Architect: TEAM IKAROS BAVARIA | FH Rosenheim, www.solar-decathlon.fh-rosenheim.de

Details: It remained exciting until the end: on the evening of the last competition day of the first international university competition „Solar Decathlon Europe 2010“ on European soil, the 17 participant teams came together for the award ceremony. Richard King, the inventor of the „Solar Decathlon“ in the US, welcomed the Decathletes. Then the winners were determined: Rosenheim took the second place – for the outstanding performance of the student „Team IKAROS Bavaria“ of the University of Applied Sciences – University of Applied Sciences Rosenheim.

Brochure: Solar Decathlon Europe 2010

Z-DECK | Deck fastening, stainless steel

The Z-DECK is a concealed, very strong stainless steel deck connector. Mounting is made easy through screwing horizontally in the board and vertically in the construction below. Through the special shape of the Z-DECK, the connector allows the wood to shrink and swell, and fixes the boards stronger than a normal screw from above.

Tests have shown a great performance of the Z-DECK with hardwoods, as well as tropical woods. The Z-DECK connector is concealed, but every board can be removed individually.

The Z-Deck connector has a special hook that hooks into a groove on the narrow side of the board. As the connector is hooked and screwed to the narrow side of the board, the connector with the board will be screwed to the joints below. At the same time, the screw allows shrinking and swelling between 4-6 mm. The connector is hidden but each board can be removed individually.

- Concealed from the first board to the last

- Very robust and can be used even for beach and boat docks

- Boards can be quickly and individually replaced

- Optimal wood protection through self-cleaning joint design

- More solid than visible screw connections from the top

- Increased security against twisting of the boards

- Connectors and screws are made of quality stainless steel

- Exceeds the requirements of Holzforschung Austria

Tips:

- Even the best connecting system cannot offset poor quality of some timber.

- Please ensure that the timber is dry; particularly, avoid timber from the core and spiral-grained boards.

- Recommended length of deck board: max. 3 meters (9.8 ft.).

- Recommended spacing: starting at 7mm

- Pre-drill, particularly with hardwoods, such as oak.

- Follow the installation instructions of your timber supplier.