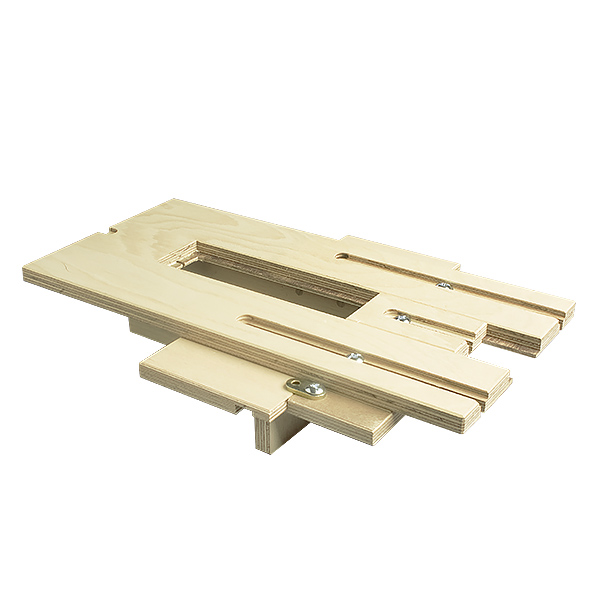

RICON®-system single connection (EA)

![]()

RICON® | The connector for main and secondary beam up to 26 kN*

System advantages:

- Applications for concealed main – secondary beam connections

- Slim profile – timber width from 50 mm upwards

- Universal access to all wood materials, steel or concrete

- High degree of prefabrication – fast and exact mounting on-site

- Elements are joint together without screwing

- Adjustment of distance between joints and building tolerances

- Fire resistance (DIN 4102-2) by 4-sided concealed mounting

- Application admissible also with interlayer

- Dismounting and remounting possible for several times

- Increased resistance to corrosion for indoor swimming pools, riding halls, stables and agricultural buildings

- ETA additionally with hardwood material

Load capacity tables

The interactive tables in Excel, available for download by clicking on the link below, provide the load capacity according to ETA-10/0189. This tool helps to quickly and easily select the connectors appropriate for the type of connection based on the service class and the type of timber.

The interactive load capacity table is available under the tab „Product downloads“