Cookies help us to use and improve our website. By using this site, you agree to the use of cookies. More information: privacy policy

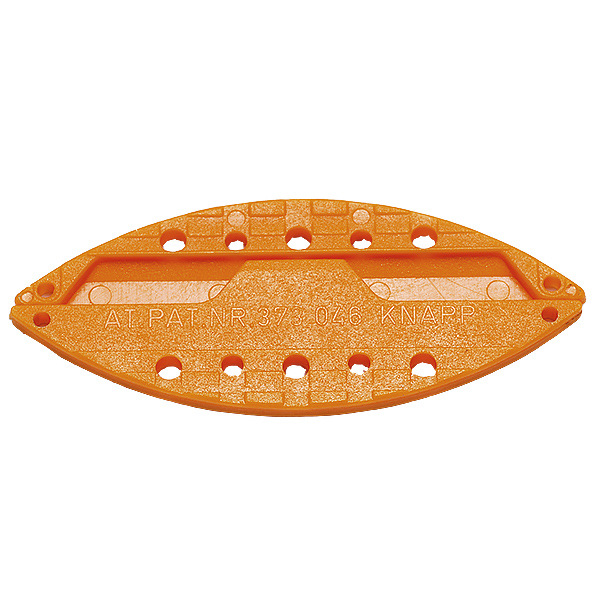

SILVER knock in slide connector, alu/zinc die-casting

SILVER knock in slide connector, alu/zinc die-casting

Immediate load-bearing sliding connector.

The SILVER connector is a universal connector made of aluminum die-cast, which is suitable for all board materials, especially for solid wood (hardwood). The two halves of the connector are easily hammered into the half-moon groove with the hammer.

The patented cutting edges are inserted in the material in the longitudinal direction and securely hold the connector in the groove. In addition, it can be reinforced with a few drops of KNAPP-Glue. To assemble the parts, first insert and then slide them in longitudinal direction into each other. The connection is immediately load bearing and can be further processed. The cabinet or piece of furniture can be installed very fast on site and therefore allows the parts to be transported disassembled. The connector is self-tightening and no longer visible after assembly. With the additional flexible flaps located on the connector, the moving of the connected parts in one or both directions can be prevented. I.e. after screwing on the back wall, a cabinet is as stable as if it had been glued. Nevertheless, complete disassembly is possible (after removing the back wall).

Processing – FITTING:

If you do not want the connection to be disassembled in one direction, you can use a hammer and the tip of another connector to bend in the locking flap. Place the connector with the tip at the beginning of the half-moon groove at an angle approximately equal to the rounding of the groove. Press in the direction of the groove slightly and make sure that the connector halves are inserted mirrored to each other. Use a hammer to make the SILVER slide along the rounding of the half-moon groove. Thus, the cutting edges are inserted in the component. Make sure that the connectors at the outer ends are flush with the surface of the component. In addition, the SILVER connector can be inserted with a few drops of KNAPP®Glue PU+.

Make sure that the locking flaps point in the same direction as the inserted connector. To assemble the parts, first insert and then slide them in longitudinal direction into each other. For final assembly, glue the joint before connecting the components. Depending on the material, pressing pressure is about 80 kg per connector.

Tip: For preparatory work, please refer to the general instructions.

Alloy-diecast

none

Slide connector

Knock in following the radius of the cutting edges

Concealed, self-tightening, demountable connector with integrated locking

Cutting a slot with a plate joiner (Lamello biscuit # 20) and adjust the depth of the slot by using the micro-adjustment screw of the joiner according to figure T. Insert the connector without using any glue diagonally into the pre-cut slot.

All softwoods and board materials not likely to split

Furniture, Interior design, shopfitting, clamping device for mitre joints and corners