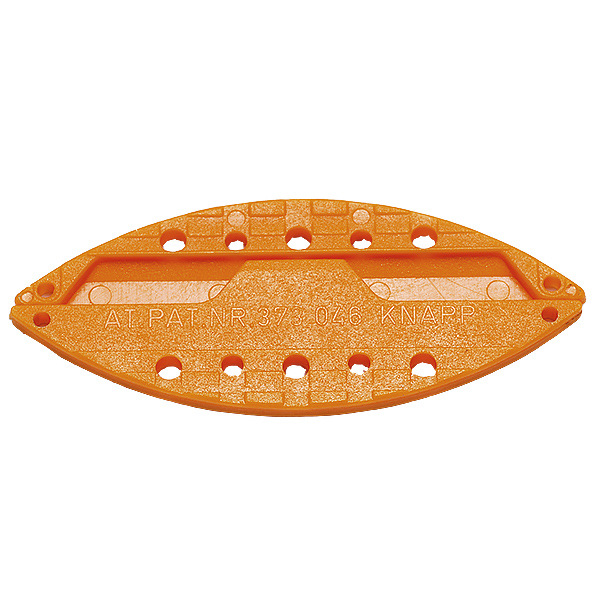

METAL slide in connector Alu/Zinc die casting

Sliding connector for high loads

The METAL is a universal connector made of zinc die-casting, and is suitable for load-bearing connections for panels and boards. The connector halves are inserted and screwed into the half-moon groove. Due to the special mold of the connector (notch on the connector’s ends), it is fixed in the groove with pan-head screws (PH screws). To assemble the parts, first insert and then slide them in longitudinal direction into each other. The joint is immediately load bearing and can be further processed.

The METAL connector is suitable for all types of connections, especially for pre-fabricated products, for example backrest for seating furniture. It allows for the products to be shipped disassembled. The connector is self-tightening and no longer visible after assembly. Due to the flaps that can be bent out at the connector’s ends, the displacement of the connector in one or multiple directions can be prevented. A cabinet is just as stable after attaching the back wall with METAL connectors, as if it was glued. Nevertheless, it remains the possibility of disassembly (after removing the back wall).

Alloy-diecast

none

Slide connector

Screw in with included PH-screws Ø 3 mm

Concealed, self-tightening, demountable connector with integrated stop

Cut a #20 slot using a suitable biscuit joiner and adjust the groove depth precisely to 12.5 mm using the micro-adjustment screw. Insert the connector mirrored into the pre-cut groove and fasten it with the supplied screws.

All wood and board materials

Furniture, Interior design, shopfitting, door frames