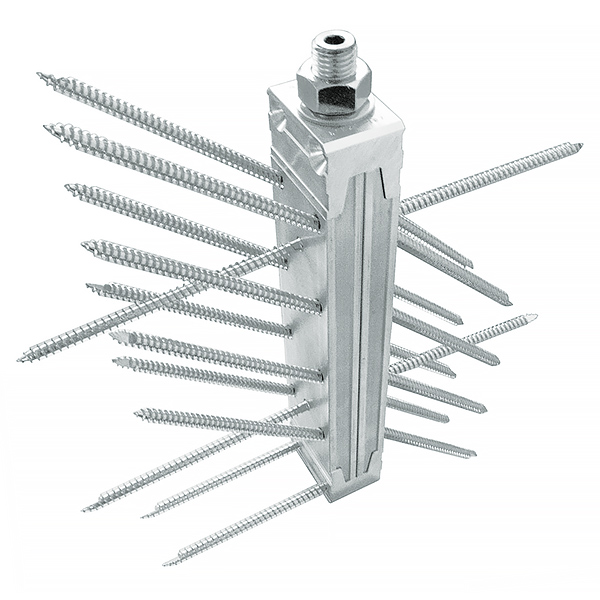

EVO GRIP™ – Variable High-Load Connector

Standard and Solo – EVO GRIP high-load connector for increased strength in timber construction

With the EVO GRIP high-load connector, KNAPP offers a powerful solution for main beam, secondary beam and column connections in modern timber construction.

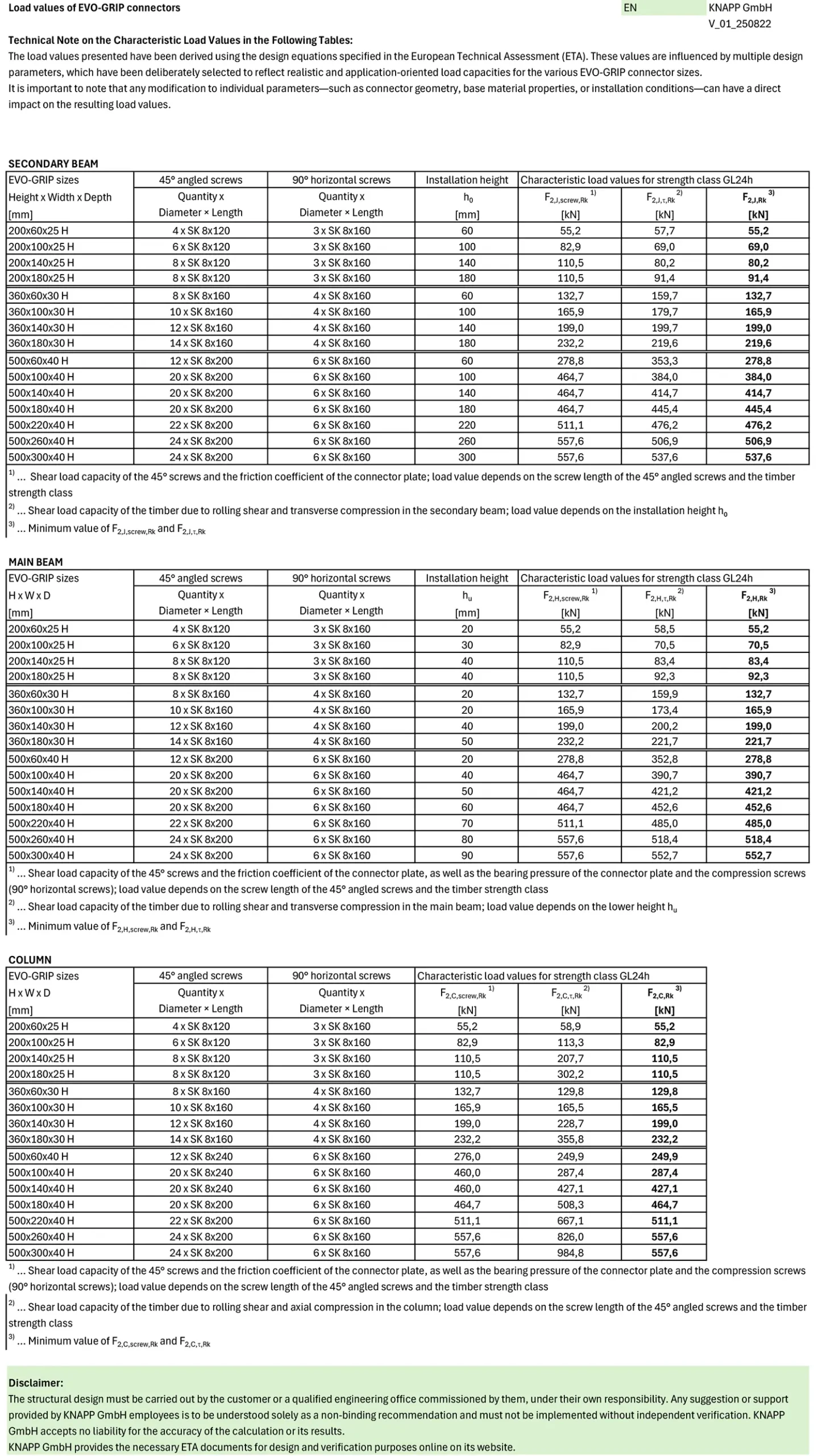

The variable connector covers medium to extremely high loads from 55 kN to 550 kN and is suitable for timber-to-timber, timber-to-steel and timber-to-concrete connections.

Flexible connections in timber-timber, timber-steel and timber-concrete

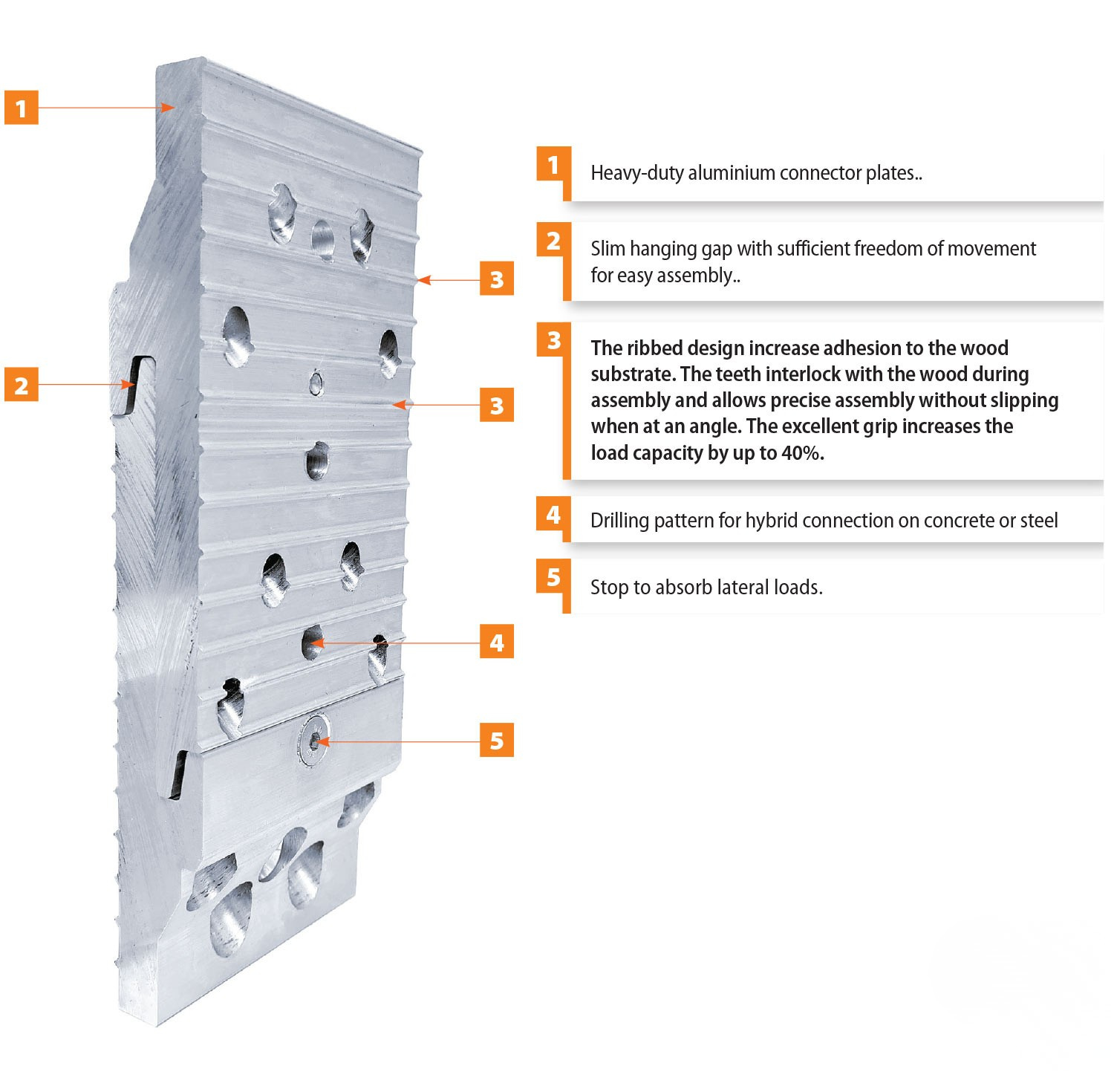

The width and height of the connector, suitable for timber-timber, timber-concrete and timber-steel connections, can be parametrically adjusted to match beam widths, load requirements and fire protection demands.

Thanks to the increased load capacity, smaller fasteners can be used, enabling greater timber cover for fire protection while providing more flexibility in designing beam cross-sections.

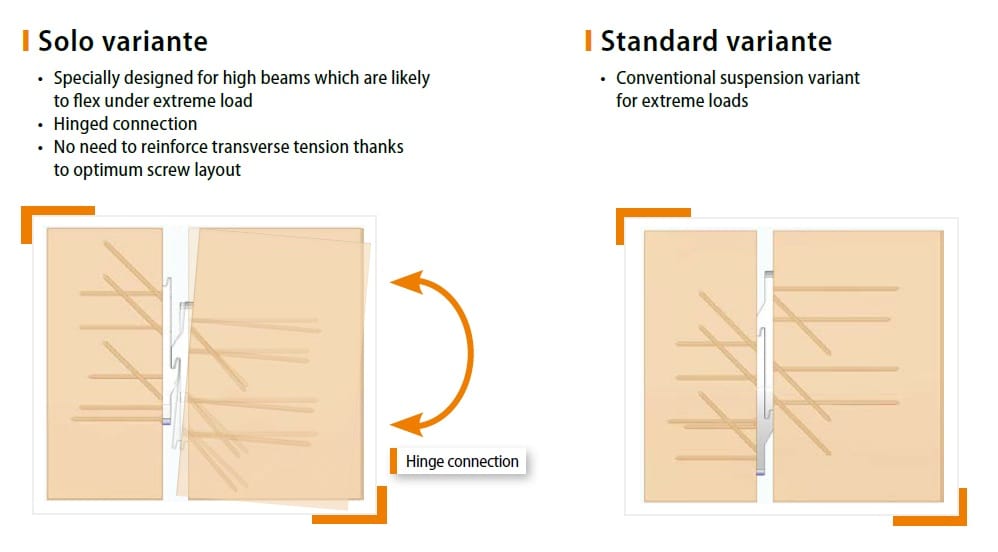

Standard variant – compact hook-in solution for extreme loads

The Standard variant of EVO GRIP serves as a conventional hook-in connection for high and extreme loads. It features a short hook-in path and sufficient installation tolerance for easy mounting.

Additionally, this variant includes an integrated lateral load-resisting feature and allows the use of comparatively smaller connector sizes despite its high load-bearing capacity.

This enables efficient and slender timber structures.

Solo variant – articulated connection for deep beams

For deep beams or beams experiencing significant deflection under load, EVO GRIP is available as a Solo variant with articulated behaviour.

Thanks to the optimal screw arrangement, additional transverse reinforcement can often be omitted.

The Solo variant provides increased rotational freedom at the connection point and is ideal for demanding engineered timber structures.

- higher load-bearing capacity for aesthetic, material-efficient designs

- Solo variant with articulated connection available for deep beams

- Standard variant available for extreme loads

- improved fire protection achievable

- flexible dimensions

- comparatively smaller connector sizes possible with the same load-bearing capacity

- variable screw pattern

- short hook-in paths with sufficient installation tolerance

Proven heavy-load connector in engineered timber construction

The EVO GRIP has already been successfully used as a wall-to-floor connector at the Lignotrend sawmill in Ibach, where it demonstrated its performance under real operating conditions.

This makes EVO GRIP the ideal choice for load-bearing connections in engineered timber construction, where high load capacity, flexibility and cost efficiency are required.

EVO GRIP – Load Capacity Table (Excel)

Functions of the Excel Tool

- Selection of different inclined and horizontal screw lengths for EVO GRIP

- Input of installation heights in the main and secondary beams

- Automatic output of characteristic load-bearing capacities and design-relevant values

- Adjustable safety factors — since National Annexes (NAD) vary by country for timber, steel and aluminium, these values can be adapted to the project requirements

Timber Engineering Support & Project Inquiry

Working on large spans, variable geometries, or complex connection details? Need assistance with preliminary sizing or connection design? – Our engineering team supports you from the initial concept through to detailed technical implementation – fast, precise, and tailored to the requirements of your project.

We support you with:

- selecting the most suitable EVO GRIP variant for your load and geometry requirements

- preliminary sizing and verification of load-bearing capacities

- interpretation of load capacity tables and ETA data

- design and layout of main beam, secondary beam and column connections

- project-specific special solutions (e.g. rail-mounted systems, hybrid connections)

- fire protection considerations and optimized screw configurations

- Together, we will develop the optimal connection solution for your project – efficient, safe and precise.