Cookies help us to use and improve our website. By using this site, you agree to the use of cookies. More information: privacy policy

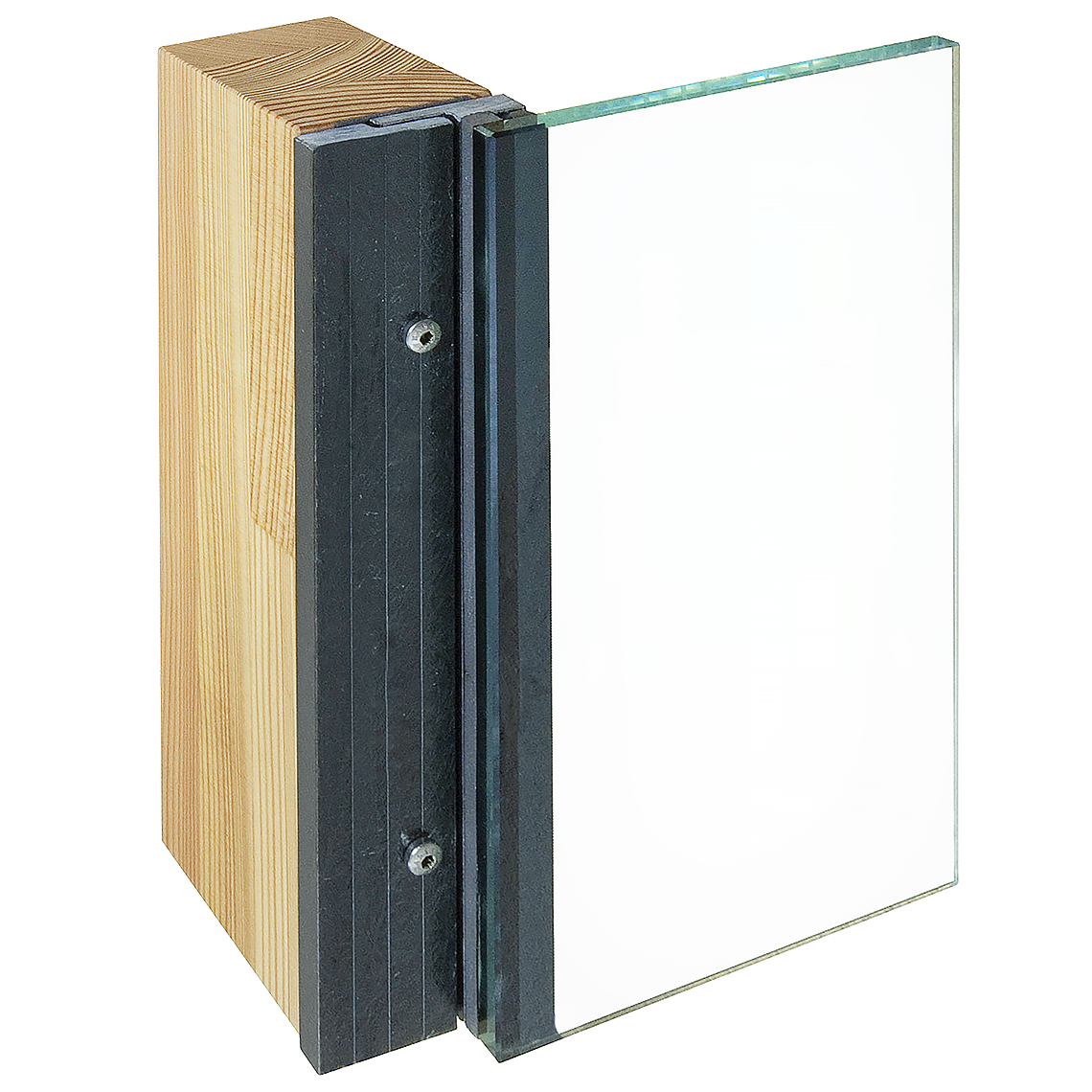

FASCO® Facade system

FASCO® Facade system

Two possible applications with FASCO®:

-

Non-load bearing fixed glazing without restriction of the glass dimension for 60 mm visible width of stud.

-

Load-bearing structural glazing for building reinforcement with an 80 mm width of the stud.

(According to the KNAPP® manual, certification pending from the German Construction Institute.

Window and door openings can be integrated flush with the façade.

The high-quality gluing between glass and FASCO®-Profile by certified and authorized personnel is essential.

Requirements for buildings and geometry of the HGV element – FASCO® profile (load-bearing)

The following points are based on the KNAPP® manual, which is published by Holzforschung Austria. It is for the use of wood-glass composite elements with a structural-bearing function. Non-bearing fixed glazing is not subject to any of these requirements!

- Floor height of fixed glazing.

-

Max. two floors can be reinforced with the structural glazing.

-

Different formats of the glass elements are permitted; the narrowest and widest glass elements are dimensioned.

-

Maximum length of the glass edge of the glass element is: 3.5 m

-

Minimum length of the shorter glass edge of the glass element: 1.0 m

-

Ratio length to height of the element: L: H = (1:1) to (2:1)

-

Bonding with tested 2K-silicones (SSG)

Glass panes – FASCO® profile (load-bearing)

- Float glass, TVG or VSG according to building requirements.

-

2- or 3-pane insulating glass with supporting edge joint must be made according to EN 13022-1.

-

The fall protection (emergency stop) must be carried out by means of mechanical brackets (in accordance with building regulations).

-

The load transfer of the glass weight is carried by a mechanical bracket that is installed under the glass pane center.

Features and advantages:

Our profiles made of glass-fiber-reinforced plastic meet highest architectural and engineering demands through a statically load-bearing glazing. Large, up to two stories, glass façades can be done without any additional reinforcement.

- The slim look of the post provides architecturally sophisticated structures.

- The efficient assembly reduces the installation time by approx. 20% in comparison to common solutions.

- No reinforcement necessary – replaces wind or steel structures.

- The inner pane of the insulating glass takes over the building reinforcement.

- Low thermal conductivity by using glass-fiber-reinforced plastic instead of aluminum.

- Scientifically proven performance (2001-2008)

- Silicone weather joints allow even façade surfaces.

- Pending building certification.

Become a partner

Become a partner and profit from the advantages of this innovative glazing system.